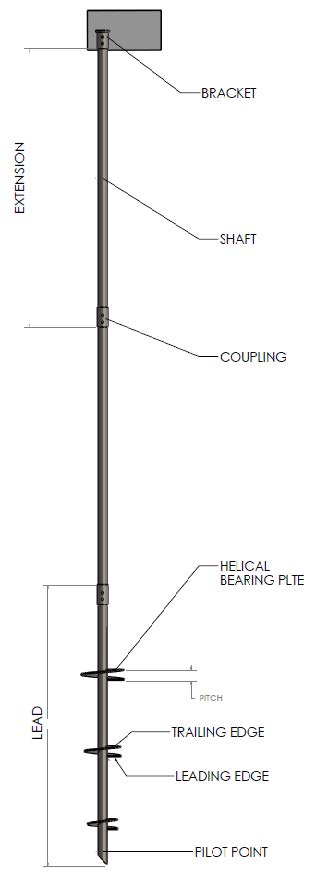

In short, helical piles are manufactured steel foundations that are screwed into the ground to support structures. The basic components of the helical pile are pictured on the left, which include the lead, extensions, helical bearing plates, and pile cap. The lead section is what is introduced to the ground first. The lead section has helical bearing plates, as shown.

Following the lead section is the extensions that are used to advance the lead section deeper into the ground. Extensions are used until the desired bearing stratum is reached. The couplings generally consist of bolted male and female sleeves and the central shaft is typically a solid square bar or a hollow tubular round section.

There are several benefits of using helical piles. We mentioned a few below:

• Cost Effective

• Environmentally Friendly (reduced truck trips, no drill spoil, etc.)

• Resist scour and Undermining for Bridge Applications

• Used for Temporary Applications

• Easily Transported

• Torque is a strong verification of capacity

• Groundwater Installation without Casing

• Reduced Installation Times (eliminate concrete curing)

• Small, Accessible Installation Equipment

• Minimal Vibrations and Noise

• Ability to be grouted after installation

• Galvanized for Corrosion Resistance